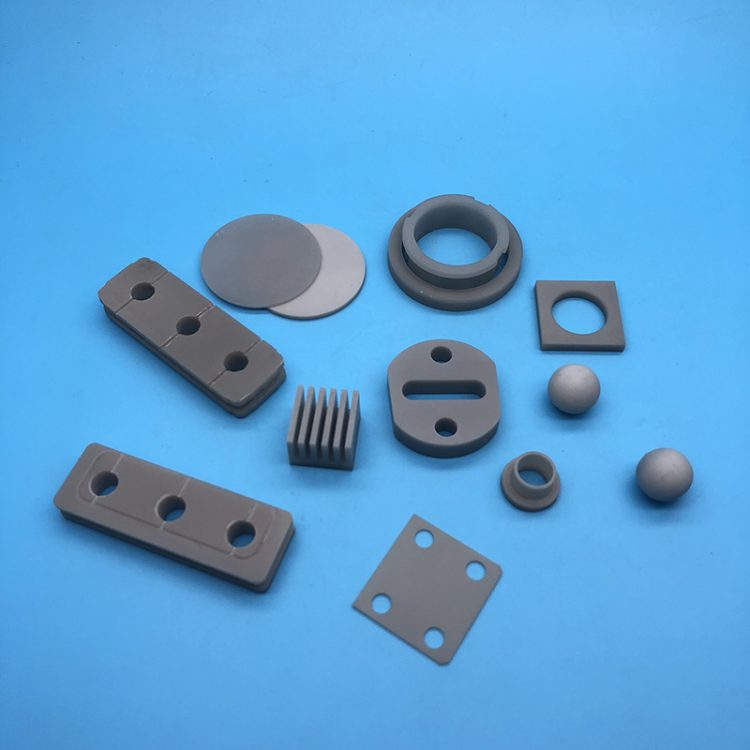

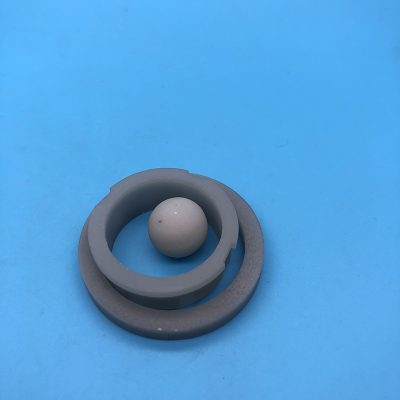

XMCERA | AlN Ceramic Component

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Aluminum Nitrides(AlN) combine high thermal conductivity with strong electrical resistance, making AlN an excellent solution for many electronic applications. Aluminum Nitrides offers CTE near that of silicon, and excellent plasma resistance, it is used for semiconductor processing equipment components.

| Properties | Units | Alluminum Nitride |

| Density | gm/cc | 3.335 |

| Color | Dark Gray | |

| Flexural Strength(MOR) | Mpa | 382.7 |

| Elastic Modulus | Gpa | 320 |

| Poisson’s Ratio | 0.24 | |

| Compressive Strength | Mpa | 2500 |

| Hardness | Gpa | 10 |

| Thermal Conductivity | W/m°K | 170 |

| Maximum Use Temperature | °C | 800 |

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Performance:

① Good optical transmission characteristics.

② Various electrical properties (dielectric constant, dielectric loss, bulk resistivity, dielectric strength) excellent.

③ Good mechanical properties, fold strength higher than Al2O3 and BeO ceramics, can be sintered under normal pressure.

④ High thermal conductivity (about 320W/m·K), close to BeO and SiC, which is more than 5 times that of Al2O3.

Application:

① The hardness of aluminum nitride is higher than that of traditional alumina, and it is a new type of wear-resistant ceramic material.

② Aluminum nitride powder with high purity, small particle size and high activity is the main raw material for manufacturing aluminum nitride ceramic substrates with high thermal conductivity.

③ Aluminum nitride ceramic substrate, high thermal conductivity, low expansion coefficient, high strength, high temperature resistance, chemical corrosion resistance, high resistivity, low dielectric loss, is the ideal large-scale integrated circuit heat dissipation substrate and packaging materials.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

XMCERA engages in R&D, manufacturing and selling the products of advanced ceramic materials including Aluminum Nitride, Aluminum Oxide, Zirconium Oxide, Boron Nitride, Silicon Nitride, Machinable Glass Ceramic and other advanced materials. Through different manufacturing processes. We supply metallized ceramic components, alumina heater, ceramic pump components and other ceramic components as request.

XMCERA is a professional high-tech enterprise, it has 15 years history of R&D, manufacture and sales in advanced ceramic materials. We have ISO9001:2015 and ISO14001:2015, also cooperate with Chinese University in advanced materials. Many products are awarded as hi-tech products and obtain patents.