Ceramic Finishing Capablities

Ceramics and more…

We provides a complete range of precision finishing options to make your fine ceramic components a functional part or assembly, including:

Shaping

- CNC grinding

- Laser machining

- Cutting

- Lapping & polishing

- Laser finishing

Coating

In addition to machining ceramic components, it is also possible to coat them. The type of coating is selected according to the application or environmental conditions and can therefore have different objectives.

- Treatment before coating

Sand-blasting

Glazing - Metallization paints

Moly-manganese

Tungsten-manganese

Moly-tungsten-manganese - Base materials for metallization

Aluminum oxide

Beryllium oxide

Sapphire

ALN

ZTA

Zirconia

BRAZING, BONDING, & JOINING

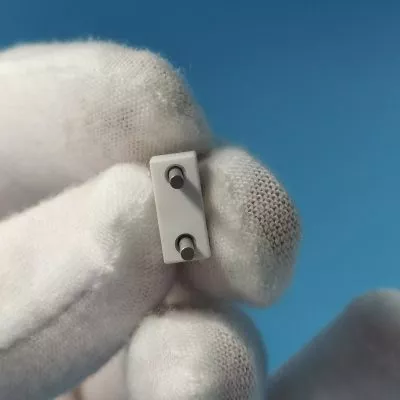

Ceramic to Metal Joint

In order to connect complex ceramic components to each other, XMCERA offers connection solutions based on metal inserts. Since it is not practical to attach threads to the ceramic components themselves, these must be made of a different material. These are adapted to the corresponding application conditions of the component, such as temperature or chemical environment. If the inserts or sleeves (e.g. metal sleeves V2A) are bonded in the component, holes of threads in various sizes (M3-M12) can be attached. In addition, XMCERA offers epoxy resin bonding of blind and through holes as well as epoxy seals.

Ceramic to Metal Brazing

Depending on the material type and part geometry, our experienced team of engineers will select the appropriate brazing fixtures, joint design, and process best-suited to your specific application. Through atmosphere or vacuum brazing, we join metal to metal and ceramic to metal in a highly controlled environment, helping protect assemblies from oxidation. The active metal brazing process is ideally suited for assembling metal substrates to ceramic parts without metallization and is in most cases a cost-effective solution performed by our in-house team of experts. As an added value for our clients, we are also capable of joining metal components by laser, TIG, and spot welding.